After 30 years of teaching high school math in the Georgia school system, in just a few months Walter Shealy will get to pursue his “sideline” of raising beef cattle full time. “I’m retiring and looking forward to it,” he says.

He’s looking forward to it because he’s also spent those 30 years getting ready to

pursue his hobby. But to call Shealy a hobby farmer would be a misnomer. For more than 3 decades, he’s worked just as hard growing hay and raising cattle as he has teaching mathematics.

“I’ve taught everything from Algebra 1 through Trig and became the department head about 10 years ago. I mostly worked with the polar ends of students — from the cream of the crop to those students who struggle with mathematics,” he says. And with a lot of satisfaction, he adds that new Georgia’s math requirements make it the sixth toughest mathematics curriculum in the U.S.

As proud as Shealy is of his teaching career, he says he isn’t going to miss the politics of the school system. Nor will he miss the 35-mile drive between his home and ranch in Carrollton, Ga., an hour’s drive west of Atlanta, and Douglas County High School in Douglasville, Ga., a suburb of Atlanta.

Meet the Rural Lifestylers: Walter and Rhonda Shealy, Carrollton, Ga.

Occupation: Soon to be a retired high school mathematics teacher. After 30 years in the Georgia school system, Walter Shealy will be giving his full attention to operating his farm and raising commercial cattle.

Property: Approx. 250 acres of pasture and hay fields owned and rented by Walter and Rhonda Shealy along with Walter’s mother.

Animals: 87 brood cows and 3 service bulls.

Equipment: Four Massey Ferguson tractors (100-HP, 65-HP, 47-HP and 22-HP); several loaders and other tractor attachments including forks, spears, buckets and grapples; several mowers including Woods grooming mower (5 ft.), Rhino mower (15 ft.), Rhino mower (6 ft.), Kuhn 7-disc mower, Kuhn 7-disc conditioner, Kuhn 8-disc wheel rake, New Idea roller bar rake, New Idea 10-ft. “fluffer,” Kuhn 17-ft. “fluffer;” two New Idea round hay balers; Tye no-till drill; various trailers; two sprayers — 50-gallon Vann and 300-gallon Ag South; AGCO backhoe (7 ft.); land roller (8 ft. x 36 in.); post hole diggers; Shaver post driver; Baltimatic fertilizer spreader; Polaris Ranger UTV; Arctic Cat 400 ATV; 2 scrapers — Rhino (7 ft.), Woods (6 ft.)

“I love my job but I hate the drive,” he says.

As he embarks upon his second career, he’s going into it with eyes wide open. He knows what equipment he needs and what he expects from his equipment dealer.

He ‘Became’ a Farmer

Considering how seriously he regards his work — both teaching math and raising cattle — the most surprising thing about Shealy is he wasn’t raised on a farm nor did he initially study math in college. But it was his college work that brought him to farming.

In 1980, Shealy graduated from Berry College in Rome, Ga., with a degree in music. He followed that up with a Masters in Music Education from the Univ. of West Georgia in Carrollton. “I lived with my grandparents while I worked on my Masters Degree because the college was right down the road from their farm. I was out here on the farm and got to love it and just started doing it,” he says.

“What farming I did, I did with my grandfather. I came down here in ’81, bought my first tractor, a Bush Hog and a little blade to grade driveways,” Shealy explains. He also started baling hay with a “baling outfit that had been well used.

“All I could afford was a Massey Ferguson 230. But I also needed a tractor to pull the hay rake, so I found an old model 1960’s Ford gas burner, but it had only 4 speeds to rake hay with.”

When his father retired, he bought the farm behind the grandfather’s spread, and Walter and his father formed a partnership where “we went in together on everything,” including farm chores and buying what equipment they needed.

Serious Cattle Business

It wasn’t until 1985 that Walter bought his first farm, which consisted of 12 acres adjoining his father’s land. By that time, his grandfather was experiencing health problems, and Shealy and his father were handling nearly all of the farm’s workload, which consisted mostly of haying and raising cattle.

Walter and his father started out with a few “commercial cattle” and in 1986 moved into the registered Limousin business. This is a French breed that Shealy describes as having naturally lean meat. “It produces the healthiest meat on the market,” he says.

The partnership between Walter and his father worked well. He maintained his full-time teaching career while devoting his off-hours to the farm. His father handled all of the paperwork involved with raising and selling registered cattle. “He also took care of talking with customers, and there was a lot of that,” says Walter. “Everyone buying a registered animal wants to know everything there is about them.”

By the time Walter’s father passed away in 1991, they had grown their Limousin business from 2 or 3 cows to a herd of 64 brood cows, 2 service bulls and about a dozen yearlings. In another pasture, they also kept 10 heifers along with 35 “just commercial cows.”

With his father’s passing, Walter’s mother became his new partner in the cattle business. He quickly discovered that his part-time passion had turned into a full-time paperwork nightmare. The recordkeeping involved with raising and selling registered animals was “unreal,” he says. Then there was the time involved with keeping the herd straight.

“I was doing it all at night after teaching school all day. Even before I could get home and go to the hay field, I had to go to the pasture and see which cow had which calf so I could get them up that weekend, tattoo them and update the records.

"On top of that, everybody that wanted to buy a bull showed up when the hay was

ready to be baled. I found out right quick that I couldn’t manage that big of a registered herd and bale as much hay as I was doing without full-time help or making some major changes,” Shealy says.

Along with his cattle business, he was cutting 60 acres of hay twice a year for his own needs. He also custom-baled another 150 acres of Fescue and Bermuda grass 3-4 times a year that he made available for sale.

In addition to seeing after his cattle business, Walter Shealy also cuts and bales 60 acres of hay twice a year for his own needs, as well as custom baling another 150 acres of Fescue and Bermuda grass 3-4 times a year that he makes available for sale.

Even though he was a part-time farmer, he found that he needed good, reliable equipment and a good dealer that he could rely on and who understood his needs.

Part Time vs. Full Time

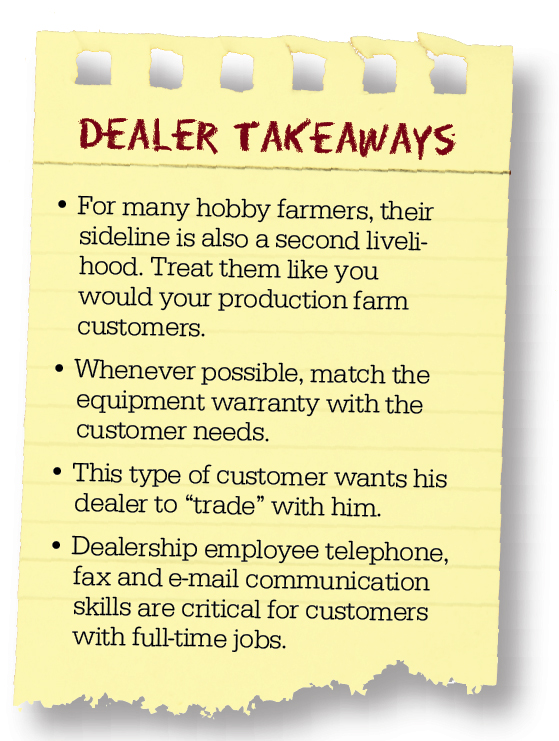

As he transitions from being a part-time farmer to raising cattle as a full-time job, Shealy says there are differences in equipment needs that dealers need to recognize.

“I try to buy newer machinery and take good care of it. In fact, some might say that I’m ‘picky’ about maintaining my equipment,” he says.

“One of the problems that you have being a part timer like me is that it takes more equipment to run part time than it does full time.” This, he says, is because he needs to have his equipment ready to go immediately when he’s ready. Organization is key. As a result, Shealy is currently running 4 Massey Ferguson tractors ranging from 22-100 horsepower.

“I plan everything ahead of time. If I’m going to use 3 pieces of equipment the next day, I need to get all 3 ready to go the night before,” Shealy says.

Planning is even more critical during the school year. “I need to have everything fueled up and hooked up. I just don’t have time to waste when I get home from school. This has been especially true since I became the department head, which has added about an hour a day to my work schedule.”

Another “subtle” difference between being a part-time and full-time farmer involves equipment warranties, according to Shealy.

“One thing you’ll find when you do this part time is that full-time farmers will run fewer pieces of equipment more hours per year, so warranty programs can work out pretty well for them. But for us part timers, it’s a different story.

“Instead of running 3 pieces of equipment for 500-600 hours a year, I’m running 4 pieces of equipment and 3 of them may get used for 250 hours or so, and the other piece for a 100 hours or less. So we don’t usually run into high-hour type maintenance issues. Our problem is that maintenance issues creep up after the equipment’s out of warranty. I’ve had tractors develop problems that weren’t anywhere close to the hour warranty, but were beyond it in terms of the age of the tractor. Technically, the manufacturer and dealer don’t have to help you at all. But when they do, even if it only saves a few hundred dollars, it goes a long way to building loyalty. It certainly has for me.”

But more importantly, Shealy says, if the dealer is looking out for his customer, he’ll get him into the right program for his circumstances.

“I expect the dealer to do his best to get me into the right warranty situation. One thing the manufacturers are beginning to do is offer different warranty programs to choose from, which is good because certain parts of equipment wear with age and other parts wear by use.”

Building a Relationship

While Shealy may be a part timer, he expects his equipment dealer to hold him in the same regard as a full-time farmer. That includes being responsive to his needs, communicating with him and being willing to “trade.” This is why Roger Harrod of Georgia Deer Farm & Agri-Center in Roopville, Ga., the local Massey Ferguson dealer, gets Shealy’s business. He’s been working with Harrod since “1995 or ’96.”

Roger Harrod, owner of Georgia Deer Farm & AgriCenter, has been working to meet Walter Shealy’s equipment and service needs since 1995. On his willingness to “trade” with Shealy, Harrod says, “I know Walter takes care of his equipment. That kind of customer isn’t hard to deal with."

“My father always said that 80% of farming is fixing what’s broken. When I’ve got hay on the ground I have no time to waste. It’s important that Roger has people who can communicate,” Shealy says.

“If I need to order parts, some times I have to call during my break and I’m not always sure what the part I need is called. I might call it a gadget and Roger’s parts people might call it a widget. Having somebody at the dealership that can communicate effectively and understand what I need is important.

“There have been times when they put the mechanic on the phone because I couldn’t get a close enough description of what’s in their parts book. By talking to the mechanic, we’ve always been able to figure out what I need.”

He says that he also appreciates that his dealership has computerized everything from part numbers to his equipment’s maintenance history.

“With other dealers in the paper-and-pencil days, I remember having to turn around and go home if I forgot to bring a part number with me. With Roger’s computer system, it’s been really nice that I don’t have to look the numbers up any more because they’ve got it all on file.”

Up to that point, Shealy had only bought some incidental pieces and some hay baling equipment from the Georgia Deer Farm dealership. “When I needed to buy a smaller tractor, I traded with Roger. I think it was a 263 with a loader and since then I’ve been dealing with him pretty much exclusively.”

Maybe the one thing that sealed the deal between Shealy and his dealer is the fact that Harrod was willing to “trade” with him. “Being part time, one thing that’s hard for me is to sell used machinery. I can’t be home to market it, and if I put it on the web, I’m answering the phone or returning calls constantly.

“One reason I like working with Roger is that he and I can come to fair terms on trades. He’s not afraid to take in used equipment that’s been taken care of, and he knows I take good care of my equipment.”

But other things have served to cement Shealy’s relationship with Harrod. Like on Mother’s Day, 2008, “when a tornado leveled us.”

By the next day, Shealy recalls, two-dozen people, including his equipment dealer, were there helping him clean up the devastation. “He immediately got my tractors into his shop and got them running so they could be used in the cleanup. You can’t buy service like that,” Shealy says.

Harrod also took much of the burden of working with the insurance company off of Shealy’s shoulders. “He wrote everything down that I needed to show the insurance company, including a parts list and a repair estimate for the machinery that needed fixing or replacing. Two weeks after the tornado hit, he and I sat down and he prepared everything I needed for insurance. There was never a question from the insurance company about one cent of it because they knew it was right.”

A Bad Dealer Experience

Shealy has come to appreciate his relationship with Harrod because not all his experiences with dealers have been good. One in particular still lingers with him.

While devoting full time to his career as a high school math teacher, Walter Shealy also works 250 acres of rolling pasture land and hay fields while raising nearly 100 head of commercial cattle on his spread in Carrollton, Ga.

He had taken his previous UTV to another dealer for maintenance. After getting it back, Shealy discovered that they hadn’t touched half of what he was billed for.

“The reason I took it there was not because I was incapable of doing the work myself. It was because I didn’t have time to do it. So I took it back over and showed the manager. He calls the guy that worked on it and asked him about it, and what was the kid going to say?

Of course he said he did everything on the invoice. So I just looked at them and said, ‘Well, guys, I’m going to tell you just like it is. I was about to buy a new tractor but you are not in the picture.’ Since then, there were times I could have bought parts from them, but I’d go to another state before you’ll see me back there. They’re not going to get any of my business,” Shealy says emphatically.

That dealership has since changed ownership and the new owner has offered to make the past situation right. But Shealy says he’s having none of it. “If I have to go to the owner to make it right, there’s no reason for me to deal with him. If I can’t trust his people, I don’t need to do business with him.”

Sticking with His Dealer

Asked what it would take to get his business away from Georgia Deer Farm & AgriCenter, Shealy says, “It would take Massey Ferguson falling apart. I like Roger, he’s a good dealer because he and I trade.

"I also like the equipment he sells. And it helps having a dealer who knows what you really want. I’ve been there looking at equipment, and Roger has said, ‘You’re not going to like this Walter, because it doesn’t have what you’re used to on it.’

“I was looking at something one time and he says, ‘Walter you’re used to a hydraulic transmission and a hydraulic reverser. You’re not going to be happy with anything less.’ Both of us knew he was right.”

Post a comment

Report Abusive Comment