Industrial hemp production is not just an opportunity for large ag equipment sales. Hammond Tractor, a John Deere dealer with 3 locations in Maine, has had a good year selling compact tractors, rototillers and even tractor mowers to hemp producers for weed control.

This is the first year for large-scale commercial hemp production nationwide as the 2018 Farm Bill changed federal policy regarding industrial hemp, including the removal of hemp from the Controlled Substances Act and the consideration of hemp as an agricultural product. Previously, the 2014 Farm Bill allowed for state departments of agriculture or universities to grow and produce hemp as part of research or pilot programs.

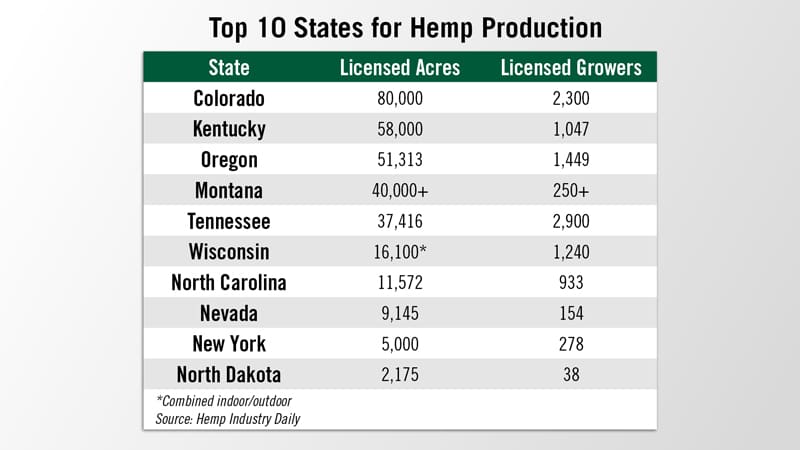

At least 47 states have now enacted legislation to establish industrial hemp cultivation and production programs, according to the National Conference of State Legislatures.

Hammond Tractor sells compact equipment to hemp producers to help them manage weeds during early growth, before the plants develop a canopy.

Supporting Producers

Ben Blackwell, salesperson for Hammond Tractor, has been working closely with farmers as they work through production issues for a new crop. “Knowledge is the No. 1 tool. Every day, I learn new things,” Blackwell says. He does a lot of research online and also recently attended the NoCo Hemp Expo in Denver. He credits the leadership team at Hammond Tractor for supporting him as he learned about hemp production.

Producers have been trying out different production methods, starting with planting. Hammond sells Maschio-Gaspardo seeders that work well for the smaller hemp seeds. Others are transplanting seedlings using mechanical transplanters from Rain-Flo Irrigation, Holland Transplanter Co., Mechanical Transplanter Co. and Checchi & Magli.

Weed suppression has posed a huge challenge in the early stages of growth before the plant reaches about 3 feet and the canopy can suppress weeds. There are limited herbicides registered for weed control in hemp. And, organic producers avoid herbicides altogether. Some use plastic mulch.

Blackwell has been working closely with producers to find solutions that work for their operations, which range from 10-800 acres in his areas. For instance, large ag tractors using GPS guidance and cultivator are an option when the hemp plants are very small and the cultivator can travel over them.

After about 6 weeks of growth, however, producers have had to focus on cultivating between the rows, which are generally are 72 inches apart. Hammond Tractor customers are using compact tractors with rototillers from John Deere, Land Pride or Woods and, for smaller fields, even John Deere lawn tractors with rototiller attachments.

“You ask 5 different farms and you’ll find 5 different ways to do something, based on their soil types or preferred production methods. I’m on farms every day and I work hand-in-hand with them. They come to me with questions and we work together to come up with a solution,” Blackwell says.

He says producers are cultivating at least weekly and larger producers are on a continual schedule of cultivation.

Harvest in Maine is expected in mid-September. The area’s growing conditions are conducive to hemp grown for CBD oil. Some producers are using forage harvesters and balers. The biomass then goes to processing plants to be dried and the oil is extracted. Some smaller producers are cutting down the plant and hanging it in facilities to dry.

Blackwell says the popularity of CBD products has generated a lot of interest. “The CBD oil business is booming and producers are making some good money, but I think people are overly optimistic about it,” he says.

Still, it’s an exciting time for area producers and for Hammond Tractor. “This is the first time we’ve really seen anything new like this,” he says.

Image from Ag Equipment Intelligence

Post a comment

Report Abusive Comment