Billy Goat Industries is celebrating its 50th anniversary, boasting a portfolio of 11 debris and turf management product categories (some 90 SKUs) sold around the world. The company’s success attracted the attention of Briggs & Stratton, which acquired it in 2015.

Rural Lifestyle Dealer’s fall issue features a history of the company from the perspective of Will Coates, whose family owned the company and who served as its president from 1992 until the acquisition.

In this story, Pierre Pereira, a 12-year veteran of the company, adds his perspective on Billy Goat’s growth, sharing what’s ahead for production and product development. Pereira joined the company in 2007 as its vice president of sales & marketing and now serves as senior director of sales for North America.

Here’s how Coates describes the influence the marketing team, led by Pereira, has had over Billy Goat’s growth.

“Marketing had a seat at the table in our product planning process and marketing was very, very critical for our new product launches. One of the things that I was most proud of is a concept that Pierre came up with for merchandising our products. We chose to go vertical on dealer floor space, which allowed us to customize a display for 2, 4 or 6 products. That meant our products weren't spread out all over the floor or they weren't organized in some haphazard fashion and mixed with other brands.

“Billy Goat carved out its own kiosk, if you will, and I think that helped a lot with the branding and its recognition. In the first year or two, we saw a lift of about 37% at most dealerships that had implemented the display concept. We also really enhanced our financing and collateral material and our web presence to look like a much bigger company than we were,” says Coates.

Pereira shares with Rural Lifestyle Dealer some highlights of the company’s growth, the changing segment and what’s ahead for product development.

Rural Lifestyle Dealer: To start, how did Billy Goat get its name?

Pereira: The original concrete dust vacuum was made by a company called Clipper Mfg. and the story goes that a marketing guy at Clipper says the vacuum eats everything, like a Billy Goat, and the name stuck.

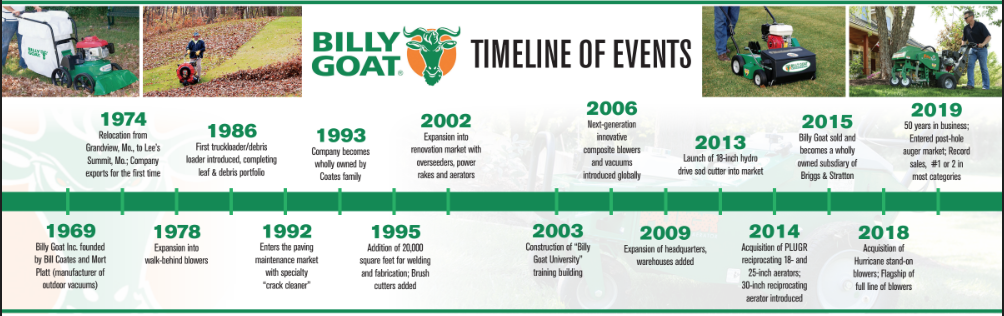

Billy Goat was purchased by Bill Coates in 1969 with partner Mort Platt, from Clipper Mfg., which was owned by Bill’s great uncles. The Coates family became the sole owners in 1993 and Will Coates, son of Bill, served as its president from 1992-2015. (Click here for more about Will Coates and Billy Goat’s evolution.)

RLD: A key part of Billy Goat’s growth has been the development of all season products. Can you comment on that?

Pereira: Billy Goat was looking for counter-seasonal products to better balance the revenues of a small company and grow the company. Our expansions over the years have included walk-behind blowers; truck loader/debris loaders; a crack cleaner for the paving market; brush cutters, overseeders, power rakes and aerators; and sod cutters. The company acquired the PLUGR brand in 2014, adding reciprocating aerators and Hurricane, manufacturer of stand-on blowers was acquired in 2018. This year, we entered the post-hole auger market.

RLD: What was happening in the industry that supported these expansions?

Pereira: I think people were generally doing more turf care (outsourced, or do-it-yourself via rental), as the country was growing and prospering. So, the idea of fertilizing, aerating, power raking and overseeding your yard, just taking it to the next level, was growing and easier to do via rental.

And, Billy Goat has always been very customer focused. Will would be in the field and listening and looking for opportunities, whether it was a trade show or talking to end users or working with dealers. He was constantly on the go, constantly had his “ear to the ground,” looking for opportunities.

Will’s goal was always to take the chore out of chore — to make it easy for a commercial user to make money and use the product. That philosophy is true to this day.

RLD: Can you comment on the changes in working with dealers and distributors regarding carrying and stocking Billy Goat products?

Pereira: It has changed dramatically. It's become much more of a business case than a stocking case. Before the recession, you typically stocked dealers or distributors on long programs — 6-month or 1-year programs. But now programs are more “just in time.” We've gone to quarterly ordering for our distributors and they love it because they can manage their inventory over a short period. Dealers have similar requirements, they don't want multiple brands and a ton of inventory, especially for seasonal lines. They just want one that they can support, turn and replenish.

So it's about replenishment, shorter stocking periods and merchandising. It's a much more sophisticated business model of dealers managing their cash and inventory, distributors doing the same, and Billy Goat offering programs that make it all work. We also offer retail financing to help dealers drive that merchandising, along with our website and social media. The whole thing ties together by driving customers into our partner’s stores.

RLD: Rental has been a strong market for Billy Goat products since the early days. Can you comment on its impact?

Pereira: The American rental industry has exploded. Today, for instance, United Rentals is a Fortune 500 company. But in the early days, rental stores were “mom and pop” businesses. A small national association was formed in the 1960s. Billy Goat saw the benefit of joining the association and for almost 50 years, the company has been an exhibitor at its trade show. We’re now one of its preferred specialty lawn and garden suppliers and we sell to thousands of rental stores throughout North America.

RLD: Can you share insight about the Briggs & Stratton acquisition and what it has meant for Billy Goat?

Pereira: There are two kinds of acquisitions: One is to purchase a company that is broken and you change it and fix it. Another is to buy a good company and add to it or accentuate it over time. We were the latter — well run, profitable, and efficient. Billy Goat fit what Briggs was looking for, a profitable company with an expanding commercial portfolio.

Billy Goat had been approached about acquisition before Briggs, but the family was very sensitive about keeping the brand and the manufacturing facility. The understanding with Briggs was that they would keep things mostly as-is and look to grow it. They’ve been true to their word. They've left the team and portfolio largely in place and have already accelerated growth with the acquisition of Hurricane blowers. In addition, Will stayed on for 3 years after the acquisition to help transition the company and has since retired.

RLD: Billy Goat products are still being produced in a manufacturing facility that was opened in 1974. How have things changed since those early days?

Pereira: The big question between Billy Goat and Briggs & Stratton is to decide what the footprint looks like for the next 20 years? That's a big decision. Do we build here on the current site? Do we find something new?

We do know it is larger, has a complementary training facility, and is probably 40% automated, providing for a state-of-the-art flow and efficiency.

Now, we have this mix of modern and old manufacturing, all in one. (View a video of Billy Goat’s manufacturing facility.) About 25% of the process is automated, such as through robotic welders, along with final manual assembly and some hand welding. We also use an electrostatic paint process, whereas in the old days, we used to wet paint everything.

RLD: What’s ahead for new products?

Pereira: New product development tends to be around productivity. Labor is a big issue, so we’re looking at bigger products that help our customers do outdoor cleanup more efficiently with less people.

Development will also continue to be around the operator experience, such as self- propelled machines, so that the products become easier and easier to use. Ergonomics and productivity will be two of the driving factors.

Battery power is definitely in our future. There is often a higher upfront cost, but there is the long-term fuel savings benefit. It’s a life cycle question for some contractors and we’re weighing the benefits now.

Post a comment

Report Abusive Comment